|

|

RESEARCH SECTIONS:

Integrated

Thermal Protection System

Micro

Mechanics and Homogenization

Composite

Materials and Structures

Multi-Fidelity

Design Response Surface Integrated Thermal

Protection System

Reducing

the cost of launching a space vehicle is one of the vital requirements of the

space industry. Reducing the cost of delivering a pound of payload into space

by an order of magnitude is one of NASAs main objectives. The space

vehicle's thermal protection system (TPS) is one of the most expensive and

critical systems of the vehicle. The TPS protects the vehicle structure

traveling at hypersonic speeds through a planetary atmosphere from damage due

to aerodynamic heating. It occupies huge acreage on vehicle exteriors and

accounts for a significant part of the launch weight.

Apollo

Command Module (Source: http://images.jsc.nasa.gov/lores/S68-55292.jpg) One

potential way of saving weight is to have a load-bearing TPS that performs

some structural functions. One such concept called the Integrated Thermal

Protection System (ITPS). Integrated

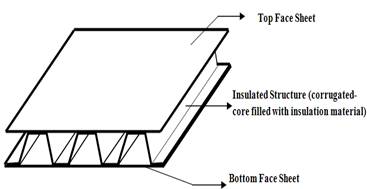

Thermal Protection System (ITPS) uses a corrugated-core sandwich

structure. A sandwich panel is a three

layer element composed of two thin flat faces separated by a thick, lighter,

and flexible core. The thin flat faces are high in stiffness when compared to

the low average stiffness of the thick core. Sandwich constructions are frequently

used because of their high bending stiffness to weight ratio. The corrugated

core keeps the face sheets apart and stabilizes them by resisting vertical

deformations, transverse shear strains, curvature in the longitudinal

direction, and enables the structure to acts as a single thick plate. Empty

spaces in between the webs can be packed with insulation material (e.g.,

SAFFIL) to block the internal radiation coming from the top face sheet. It

is expected that by suitably designing the corrugated-core sandwich

structure, a robust, operable, weight-efficient, load-bearing TPS can be

developed.

Corrugated-core Sandwich Structure concept

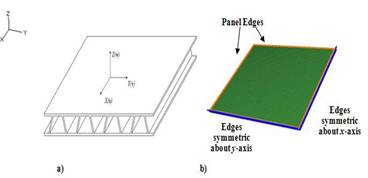

for Integrated Thermal Protection System (ITPS) 3D High-Fidelity Model: One fourth of the ITPS panel containing half the total

number of unit cells is modeled using the ABAQUS finite element (FE) software. Thermal

and pressure load is applied and linear stress analysis is done on the 3D

model. The procedure used finite element analyses to construct response

surface approximations (RSA) of the critical constraints. The RSAs obtained

were of high fidelity; however they required large computational time. This

cost is expected to increase by at least an order of magnitude when

uncertainties are taken into account and added as additional variables for

obtaining a robust design.

a)

The ITPS Panel b) Typical mesh and

boundary conditions for the high fidelity 3D finite element model of one

fourth of the panel

Micro Mechanics and

Homogenization Micromechanical

analysis of a unit cell is performed to determine the structure's extensional,

bending, coupling shear stiffness, stresses, and unit cell behavior. Thus,

the sandwich panel as an equivalent thick plate which is homogeneous,

continuous, and orthotropic. A

FE based homogenization procedure is developed to obtain the equivalent plate

properties, and also for calculating the stresses in the web and face sheets

from the 2D analysis results (reverse homogenization). The FE based

homogenization and analysis of the 2D plate is very less expensive compared

to that of 3D. Methods are developed to calculate the equivalent A, B and D

matrices, transverse shear stiffness A44 and A55 and

thermal forces NT and MT for a given through the

thickness temperature distribution.

a) One fourth of the ITPS panel,

b) Typical mesh and

boundary conditions for the low fidelity 2D finite element model Aerodynamic Pressure Load 101 kPa Edges symmetric

about y-axis Panel Edges

Reverse

homogenization for a 2D plate Composite Materials and Structures The

biggest challenge of an ITPS is that the requirements of a load-bearing

member and a TPS are contradictory to one another. A TPS is required to have

low conductivity and high service temperatures. Materials satisfying these

conditions are ceramic materials, which are also plagued by poor structural

properties like low impact resistance, low tensile strength and low fracture

toughness. On the other hand, a robust load-bearing structure needs to have

high tensile strength and fracture toughness and good impact resistance.

Materials that satisfy these requirements are metals and metallic alloys,

which have relatively high conductivity and low service temperatures. The top face sheet is a hot structure and

ceramic composites such as SiC/SiC composites are candidate materials. The

web could also be made of similar composite. From weight efficiency point of

view the bottom face sheet will be wade of graphite/epoxy composite. Thus

there are several design variables-geometric and material property

variables. The design of such a TPS will require several thousand analyses to

obtain a minimum mass design. When the uncertainties in properties,

dimensions and loads are taken into account, the computational costs will be

prohibitively high. Hence there is a need to develop efficient methods for

analysis and design of ITPS for future space vehicles.

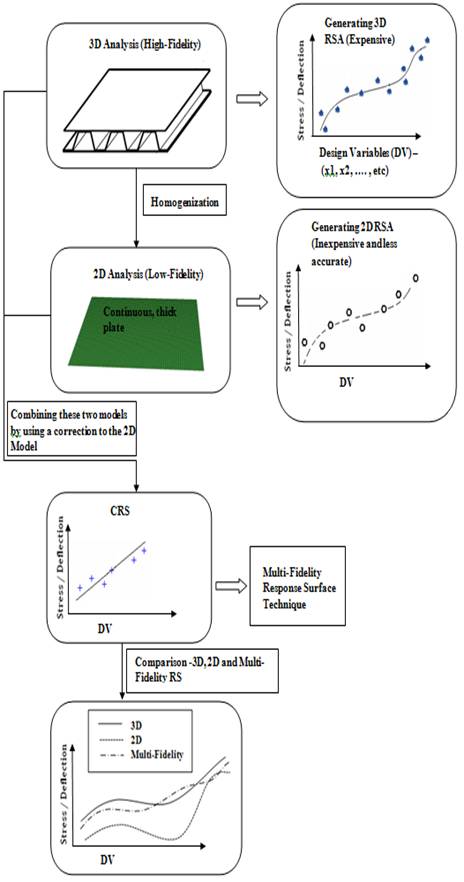

Multi-Fidelity Design

Response Surface A

three-dimensional RSA FE method of the ITPS is the expensive. The low

fidelity model RSA method is less accurate but inexpensive. We can reduce the

computation time and also improve the accuracy of the 2D by fitting it with a

high quality surrogate, which will then be corrected by the use of a small

number of high fidelity 3D FEA. Fitting the difference or the ratio between

the high fidelity analyses and the low fidelity surrogate with a response

surface approximation allows construction of the so-called correction

response surface (CRS). The entire approach, known as multi-fidelity, usually

allows use of significantly fewer high fidelity analyses for a given

accuracy.

Flow chart describing Multi-fidelity

approach |

|