Current Research Activities

This is a presentation of currently ungoing research projects in the Combustion and Fluid Dynamics Lab. For information about previous related topics, please see the Previous Research page.

Non-Premixed conditions in the flameholding recirculation region behind a step in supersonic flow

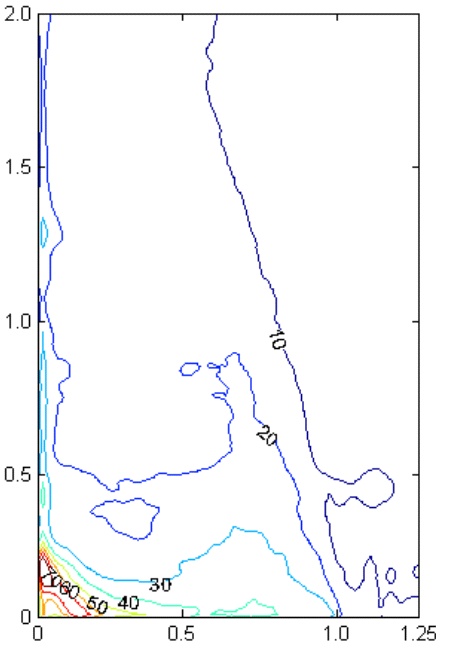

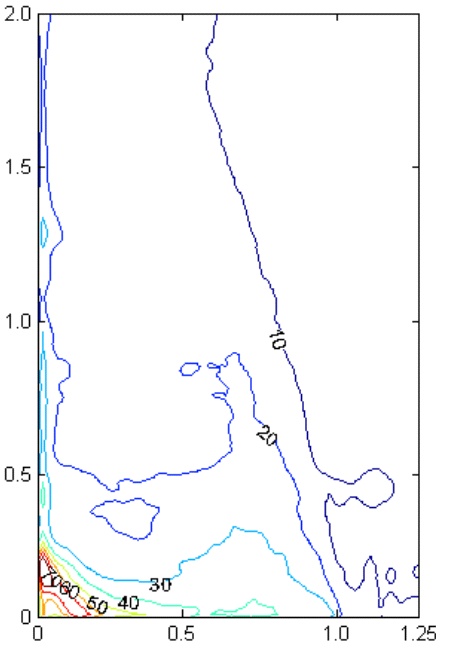

Flameholding in supersonic flow depends on local conditions in the recirculation region, and on mass transfer into and out of this region. Large gradients in local gas composition and temperature exist in the recirculation region. Hence, stability parameter correlations developed for premixed flames cannot be used to determine blowout stability limits for non-premixed flames encountered in practical devices. In the present study, mixture samples were extracted at different locations in the recirculation region and the shear layer formed behind a rearward-facing step in supersonic flow, and analyzed by mass spectrometry to determine the species concentration distribution in the region. The point-wise mass spectrometer measurements were complemented by acetone planar laser-induced fluorescence (PLIF) measurements to get a planar distribution of fuel mole fraction in the recirculation region. Non-reacting flow tests and combustion experiments were performed by varying various fuel related parameters such as injection location, injection pressure and fuel type. Fuel injection upstream of the step was not effective in supplying enough fuel to the recirculation region and did not sustain the flame in combustion experiments. Fuel injection at the step base was effective in sustaining the flame. For base injection, the local fuel mole fraction in the recirculation region determined from experiments was an order of magnitude higher than the global fuel mole fraction based on total moles of air flowing through the test section and total fuel injected in the test section. This suggests substantial difference in flame stability curve for non-premixed conditions in the scramjet engine compared to premixed flow. For base injection, fuel remained in the recirculation region even at higher injection pressure. Due to slower diffusion rate, the heavier fuel had higher local mole fraction in the recirculation region compared to lighter fuel for a unit global fuel mole fraction injected in the test section. Hence fuel molecular weight will affect the non-premixed flame stability limits in scramjet engine; the heavier fuel will have better fuel-lean and worse fuel-rich stability limit compared to lighter fuel. This is in addition to the fact that a lighter fuel such as hydrogen has a much wider flame stability limit than a heavier fuel such as propane. The data obtained in the study can help develop a stability parameter for non-premixed flames and validate computational models.

This is a continuation of earlier supersonic mixing experiments.

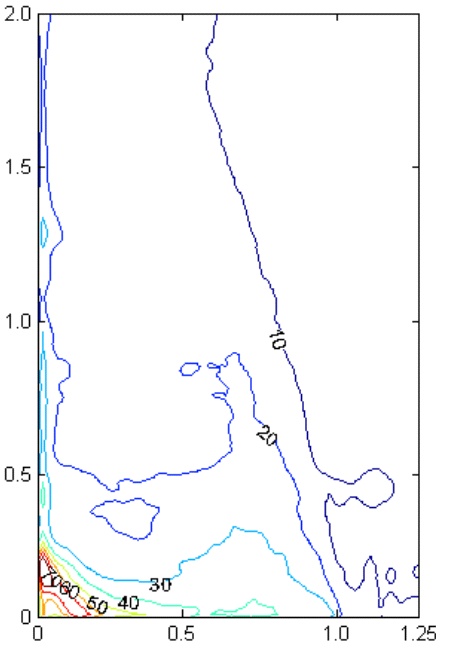

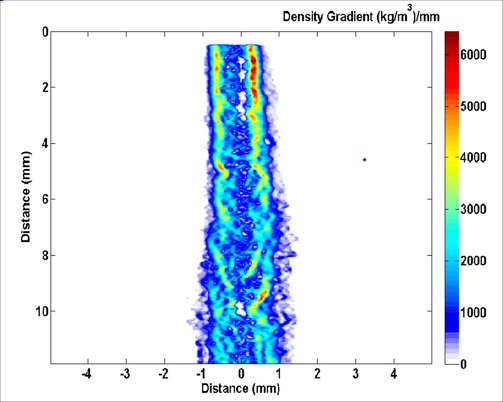

PLIF measurement of fuel mole fraction behind a rearward facing step at P0,Ar=5.4 atm.

Transverse injection occurs at (x,y)=(0,0.2), step (0,0)-(1,0).

References:

A. Thakur, C. Segal, "Non-Premixed Gases Flameholding in a Recirculation

Region Imbedded in Supersonic Flow", Journal of Propulsion and Power, July 2005 (submitted).

A. Thakur, C. Segal, " Concentration distribution in a supersonic flow recirculation region", Journal of Propulsion and Power (submitted).

Thakur A and Segal C, "Analyses of non-premixed flameholding behind a step in supersonic flow", 44th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, AIAA-2006-1380, Jan 2006.

A. Thakur, C. Segal, "Flameholding in Supersonic Flow - Non-Premixed Recirculation Region Composition", 13th International Space Planes and Hypersonic Systems and Technologies Conference , Capua, Italy, AIAA 2005-3391, May 2005.

A. Thakur, C. Segal,

"Flameholding Analyses in Supersonic Flow", 40th Joint Propulsion Conference, Ft Lauderdale, FL,

AIAA-2004-3831, July 2004.

High-Pressure Mixing and Combustion

High-Pressure Combustion

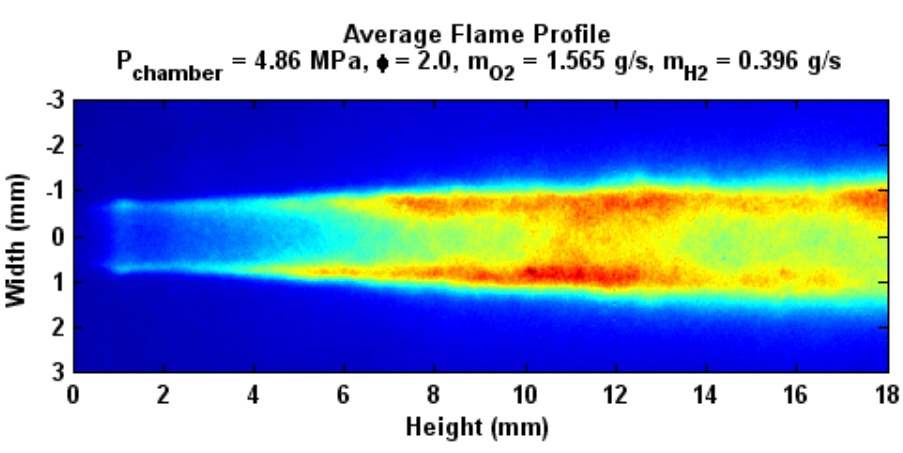

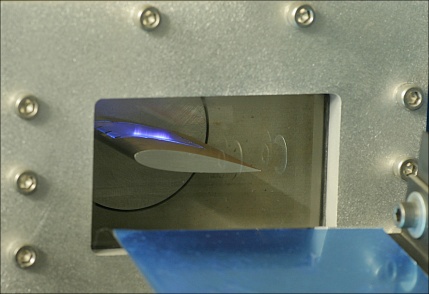

The combustion of hydrogen-air and hydrogen-oxygen mixtures under a wide range of equivalence ratios and pressures are studied in the high-pressure combustion chamber. These tests investigate the combustion processes under rocket engine conditions to provide data for CFD code validation. Pressure and temperature measurements are complemented with planar laser-induced fluorescence (PLIF) which allows the OH concentration in a plane to be determined noninvasively .

There is also a short AVI movie (25MB) of hydrogen-oxygen combusion at 100 psia (0.7MPa) here.

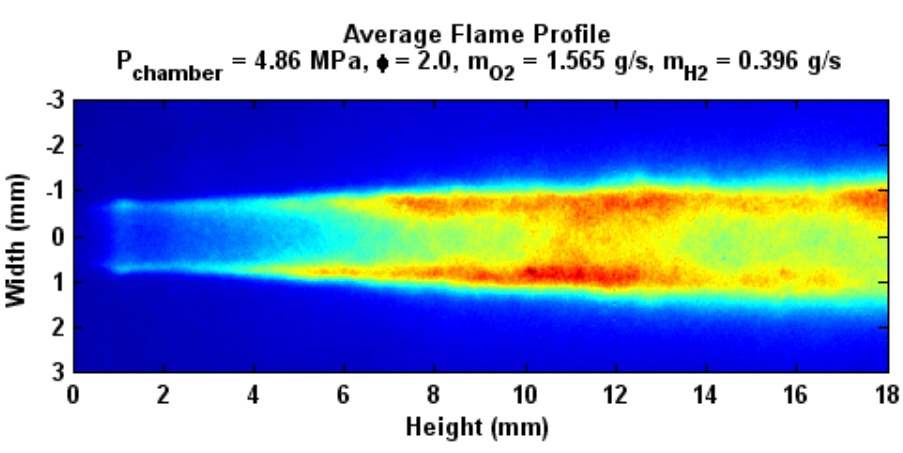

GH2-GO2 flame emission - average of 132 broadband images

References:

A. Conley, A. Vaidyanathan and C. Segal, "Heat Fluxes Measurements in a GH2/GO2 Single- Element, Shear Injector", AIAA-2006-5048, 42nd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Sacramento, CA, Jul, 2006.

Filtered Rayleigh scattering (FRS) is a new, non-intrusive measurement technique, where the Doppler shift produced when narrow-band laser light is scattered against small particles is used to quantify the velocity of the particles. This technique has previously been validated for a free jet. Building on these experiments, a refined setup using 4 ICCDs and 2 CCD cameras is now being built to measure 2D velocity components simultaneously with OH PLIF in the high-pressure combustion facility.

More on FRS

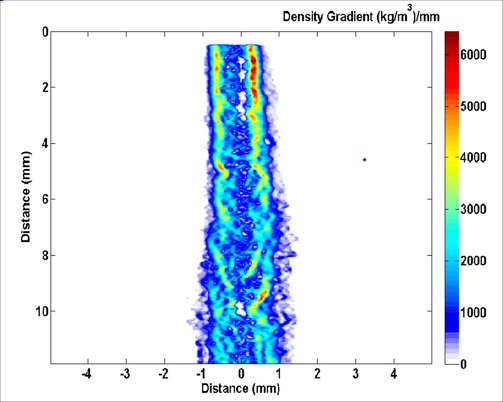

Liquid Mixing under Trans- and Supercritical Conditions

The purpose of this facility is to study jet and droplet breakup and evaporation under transcritical and supercritical conditions. Through using exciplex fluorescence techniques, the processes taking place as liquid oxygen mixes with gaseous hydrogen in a rocket engine under high pressure can be simulated. Previously conventional liquid fuels (JP-10 or dodecane) have been mixed with naphtalene and TMPD to provide fluorescence with excitation at 355 nm and detection at 490 nm (liquid phase) and 390 nm (gaseous phase). Currently, tests are carried out using a volatile fluoroketone, which is able to simulate the supercritical combustion chamber mixing of a liquid hydrogen jet.

Liquid jet injected at supercritical temperature, Tliq = 300 K, Tch = 480 K, Injection Velocity 10 m/s, Pch = 20.5 atm

Reference:

T. Tran, Y. Kochar, J. Seitzman, S. Polikhov, C. Segal, "Fundamental measurements of multicomponent turbulent spray mixing in transcritical and supercritical conditions",

41st AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Tuscon, AZ, AIAA 2005-4129, Jul 2005.

Cryogenic Cavitation Simulation

The behavior of liquid hydrogen in a high-performance turbopump is studied using a volatile fluoroketone in the new watertunnel facility. Cavitation is a major challenge in these pumps and due to the pumps raising the pressure from low subcritical pressure to supercritical pressures, modelling using water is impractical due to its high critical pressure and temperature. The fluoroketone used has more accessible critical conditions (18 bar, 169oC) and also fluoresces when excited with near-UV light, enabling PLIF to be used for density measurements. The tests currently use a NACA0015 hydrofoil, studying the thermodynamic effect, which supresses cavitation as critical conditions are approached, allowing comparison to previous research using water at different temperatures. This will allow us to build a database on the cavitation behavior of a fluid near critical conditions which will enable model development for CFD codes to be used in the design of liquid hydrogen turbopumps.

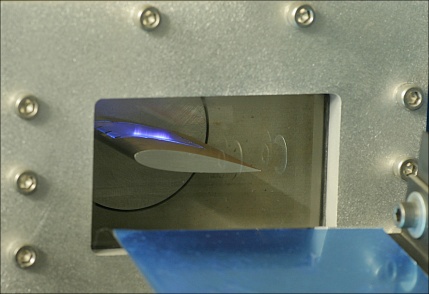

Fluorescence produced as 351 nm laser light is projected as a vertical sheet

from the centerline of a hydrofoil surrounded by fluoroketone

Catalytic Combustion

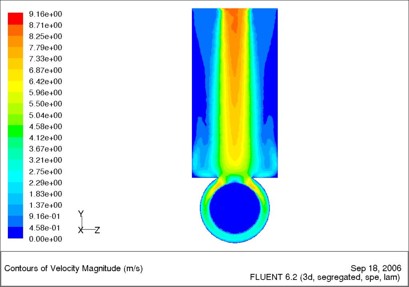

These tests study the catalysed reactions taking place in a rich fuel-air mixture as it passes through the pre-combustor stage of a low-NOx gas turbine combustor. The test facility consists of two concentric tubes where the outer surface of the inner tube is covered with a catalyst. The inner tube contains a cooling air flow while the annular region contains a fuel-air mixture that reacts on the catalytic surface. The inner and outer air flows can be independently controlled by a number of massflow controllers from Alicat, allowing equivalence ratios and fuel composition to be varied over a wide range. The incoming air streams can also be preheated through passing through two independently controlled electric heaters. Measurements are carried out using mass spectrometry of gas samples drawn from above the catalyst surface at different axial locations. In paralell with the experimental tests, CFD simulations using Fluent are carried out.

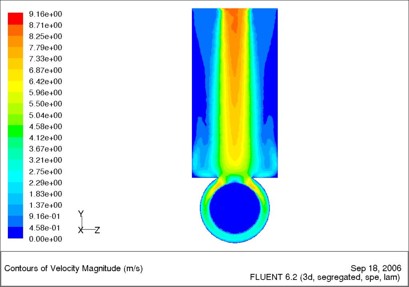

Fluent simulation output showing velocity magnitude contours in a cross-section where

the fuel and the heated air mix before being fed to the catalyst.

More

Previous research topics

Back to the Combustion Lab homepage.