Accuracy investigation of filtered Rayleigh scattering for velocity measurements

Introduction

This is a brief description of the work I carried out at the University of Florida 2000-2004

and which is the basis of my doctoral dissertation. The goal of the investigation

was to establish uncertainty bounds for filtered Rayleigh scattering (FRS) when

used for velocity measurements in a supersonic airstream with a realistic level

of impurities and condensation and identify the main sources of uncertainty as well

as suggest ways of improving the FRS accuracy.

FRS physical principle

Filtered Rayleigh scattering is a based on Rayleigh scattering, i e scattering of

electromagnetic radiation (e g light) by particles much smaller than the wavelength of

the radiation. Rayleigh scattering is elastic, i e the scattered radiation

has the same energy as the incident radiation. When the scattering particle,

e g a nitrogen molecule, is moving relative to the light source, the scattered

light will be Doppler shifted by a frequency proportional to the velocity components

of the particle bisecting the incident and scattered directions. Through analyzing

this shift, e g through using a spectral filter, knowing the geometrical

arrangement of the light source, scattered and light collector, this velocity

can be determined. Provided that the scatterers consist of the molecules of the

medium themselves, the temperature and pressure can also be determined based

on the spectrum that is produced when near-monochromatic light is scattered

against thermally excited molecules. Since the scattered light intensity is

proportional to the number of scatterers, the density of the scattering fluid

may also be determined, provided that negligible amounts of impurities

are present. Sice the scattering efficiency (or crossection) is proportional to

the sixth power of the scatterer diameter, this may present a very stringent

requirement when it comes to the purity of the scattering medium. For bulk

velocity measurements, this requirement is relaxed to having particles that

are capable of closely tracking the flow. While the difficulty of achieving this

may vary greatly depending on the nature of the flow (shock waves, turbulence etc) and

spatial resolutoion desired, it is often significantly easier to meet.

Experimental setup

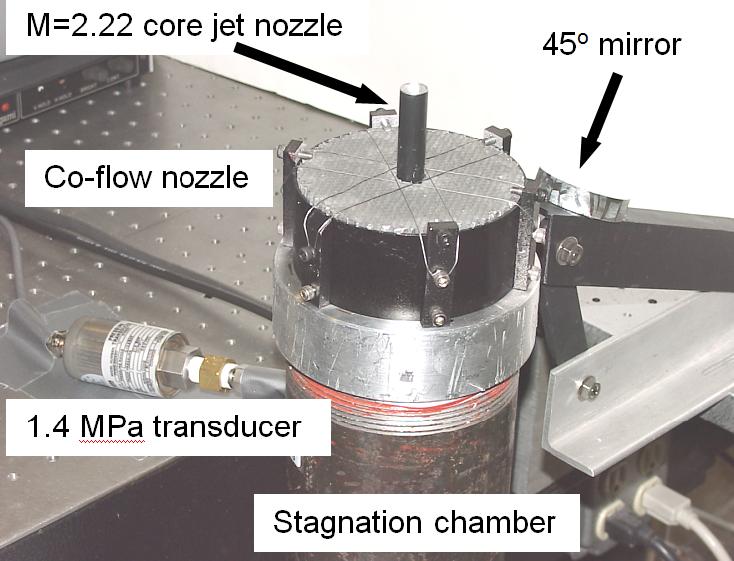

The setup chosen was designed to capture

the axial velocity component of a M=2.22 jet across the ~15 mm jet crossection. To

attain the strong enough scattered light signal without resorting to deliberate flow

seeding, an injection-seeded Spectraphysics GCR-150 laser delivering 300 mJ at 532 nm

was chosen for illumination and intensified CCD cameras (Cooke DiCam-PRO and Roper

Scientific PentaMax) were chosen for acquisition. The spectral filtering was carried

out using a 5" I2 chell from ISSI. The photo below shows how the two cameras and

the iodine cell were arranged on a separate table allowing them to be aligned with

the flow to be studied at 45 degrees angle to the jet centerline. In the picture, the DiCam-PRO camera as well as the beam splitter and the mirror used for distributing the light to the two cameras have been removed from the table.

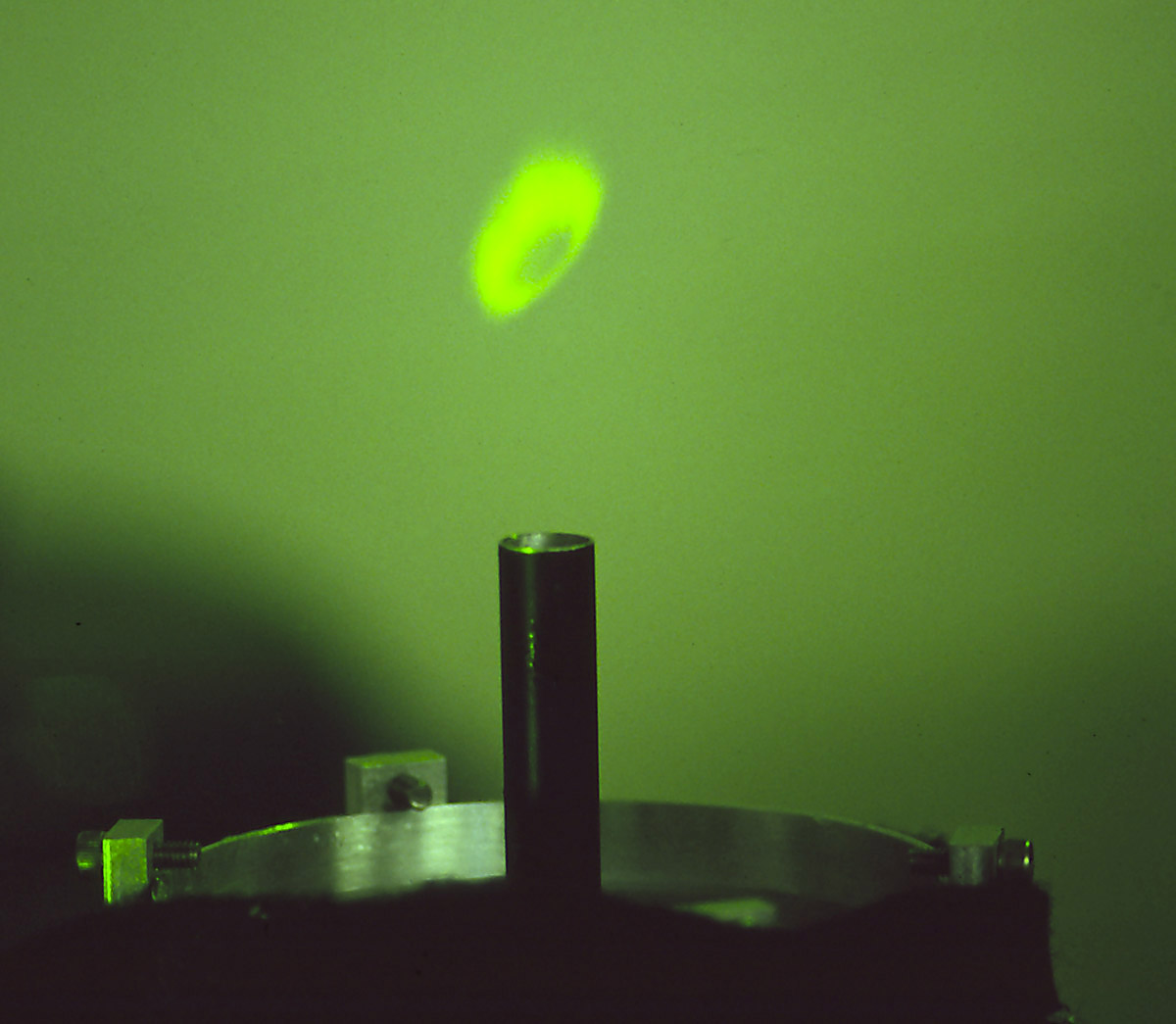

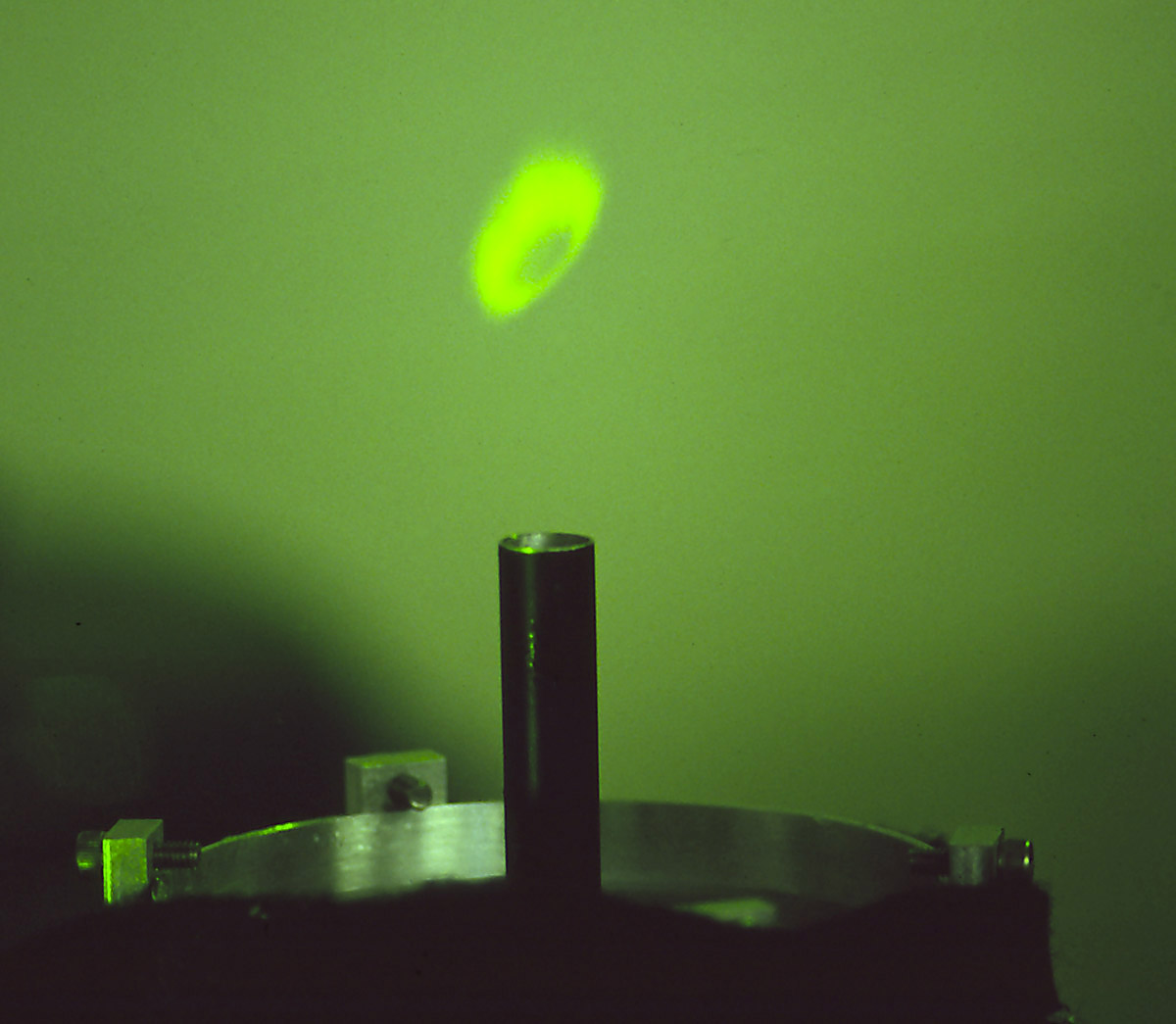

With the laser sheet passing through the jet centerline from the opposite side

at 45 degrees angle, perpendicular to the camera optical axes, the axial flow velocity

in a plane crossing the jet centerline 1.56" downstream of the nozzle exit was

studied. As the photo (taken from a different angle but with the run-time

sheet in place) below shows, condensation of water vapor

in the ambient air in the jet shear layer caused strong localized scattering.

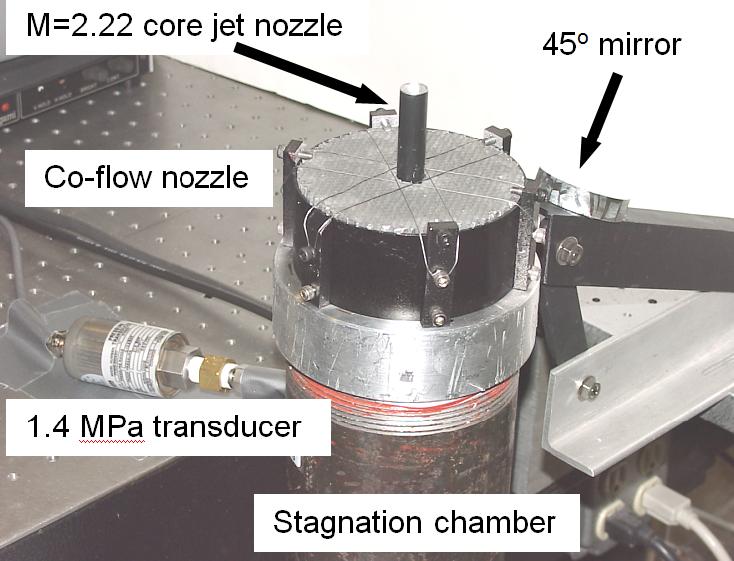

In order to reduce this droplet scatter and make the core of the jet visible, a 4"

diameter co-flow was created around the main M=2.22, 0.44" diameter jet. The 10 m/s

coflow was created through letting the same compressor air (200 psia, T0=300K, dew

point 233K) feeding the main jet pass through a number of holes in the nozzle base

and then through a ball-filled chamber and several screens to assure reasonable

uniformity. The photo below shows a side view of the entire assembly on top of a

piece of 4" pipe serving as stagnation chamber.

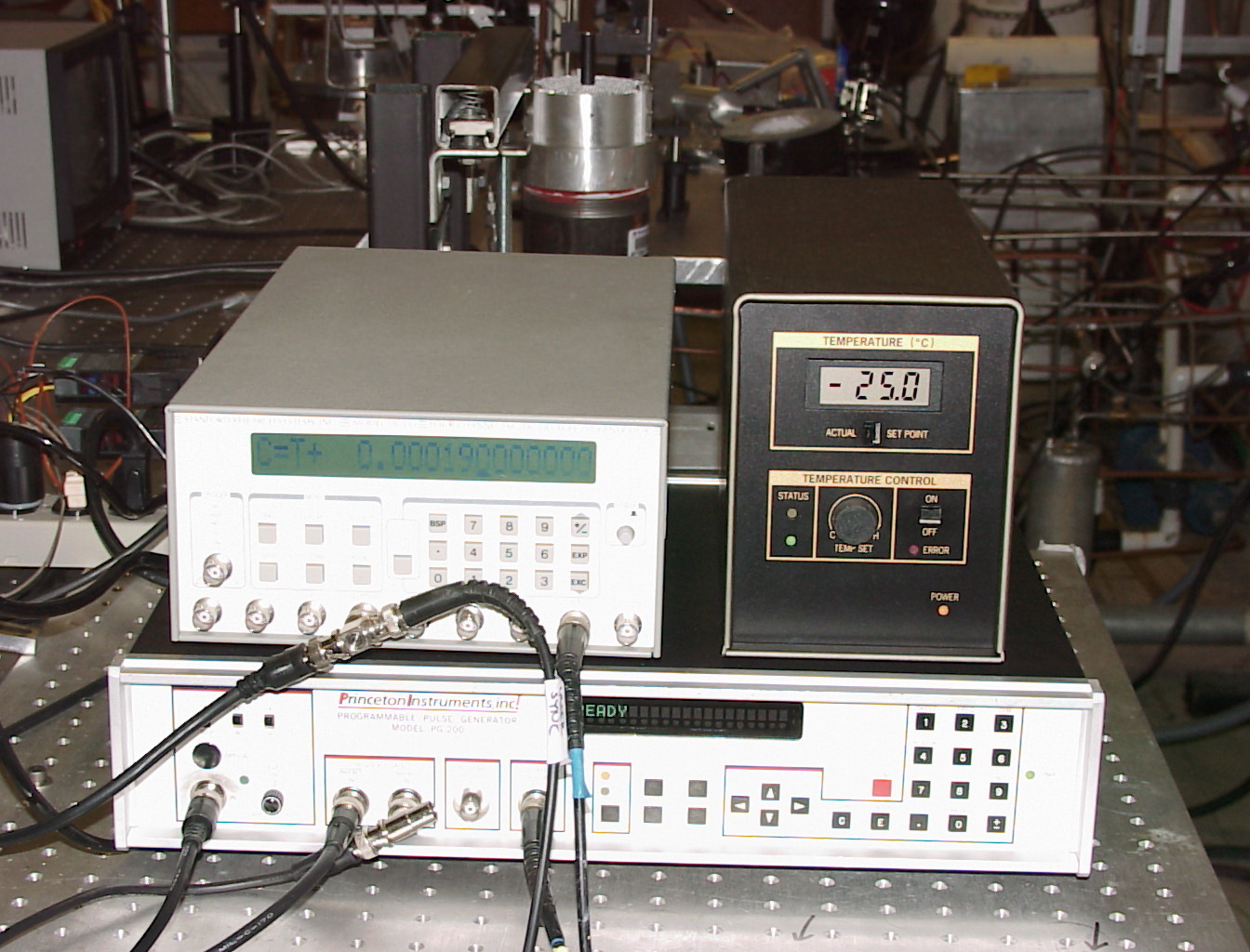

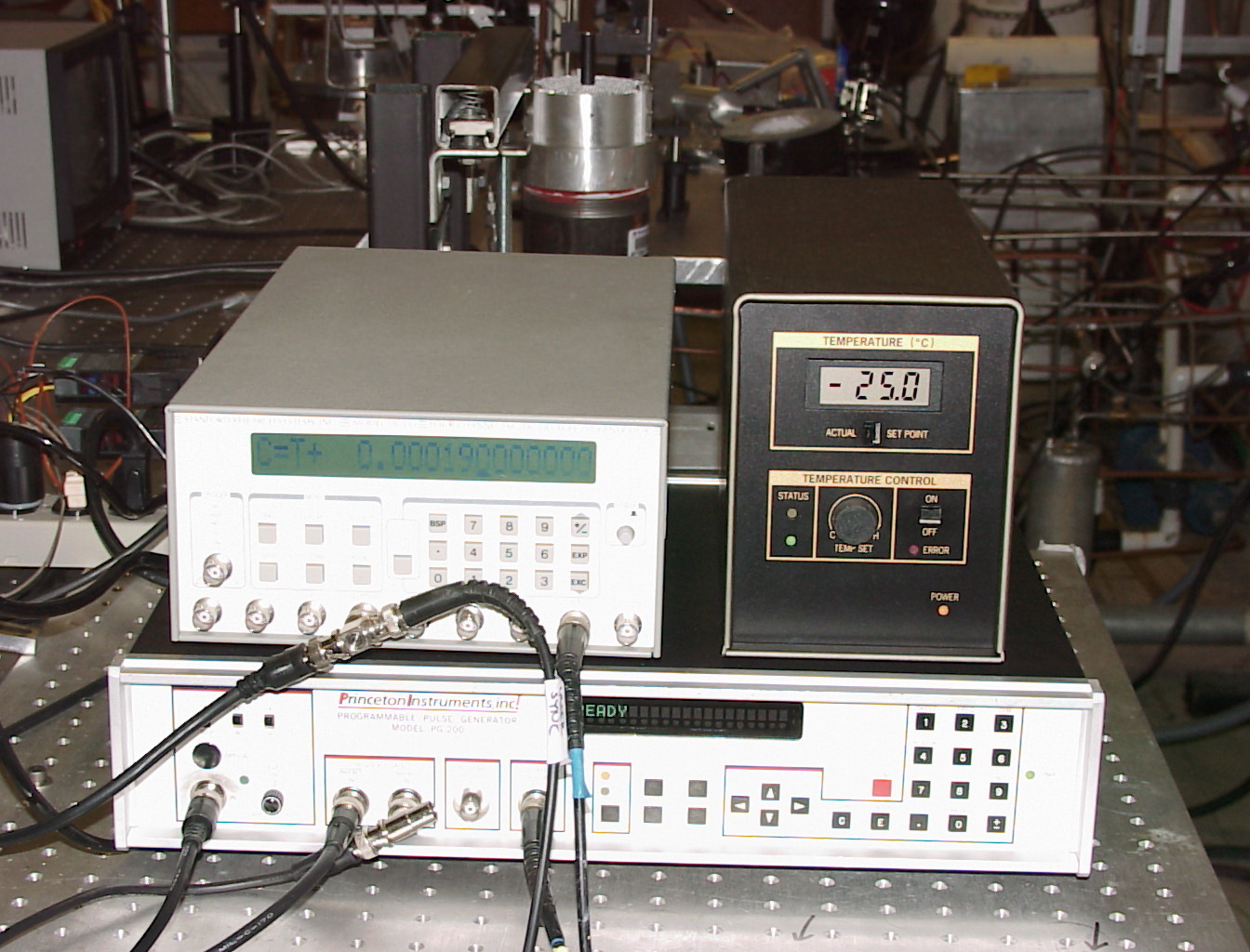

To allow the FRS experiments to be run with ambient lighting on, the gate width

of the cameras were kept at 1 microsecond. During this period of time, the laser

Q-switch was opened, giving a 10 ns long pulse of light that froze any flow features.

The experiment was controlled by a DG535 delay shown in the photo below together with

the Pentamax pulser and power supply/temperature controller.

As a comparison to the FRS results, Pitot probe measurements were carried out using

a square-cut 0.065" OD probe. The probe could also be fitted with a sharp conical tip

with static taps on the surface, allowing the static pressure to be measured at each

point as well.

Results

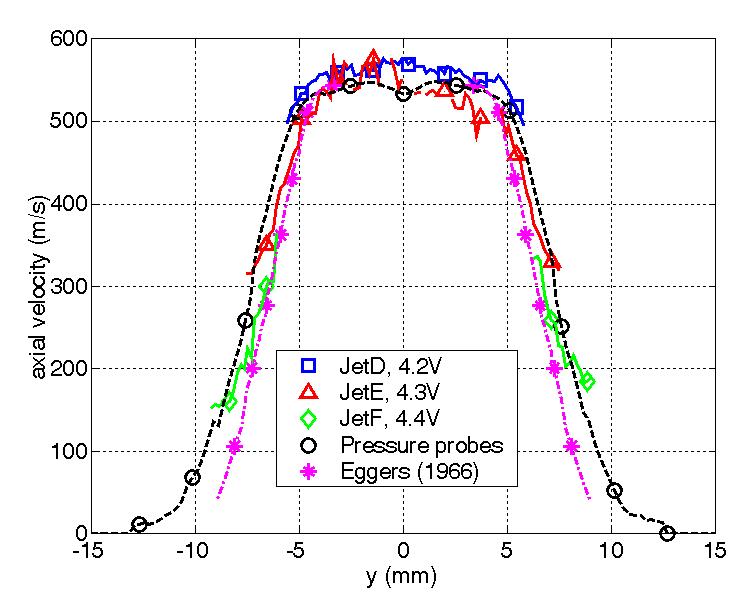

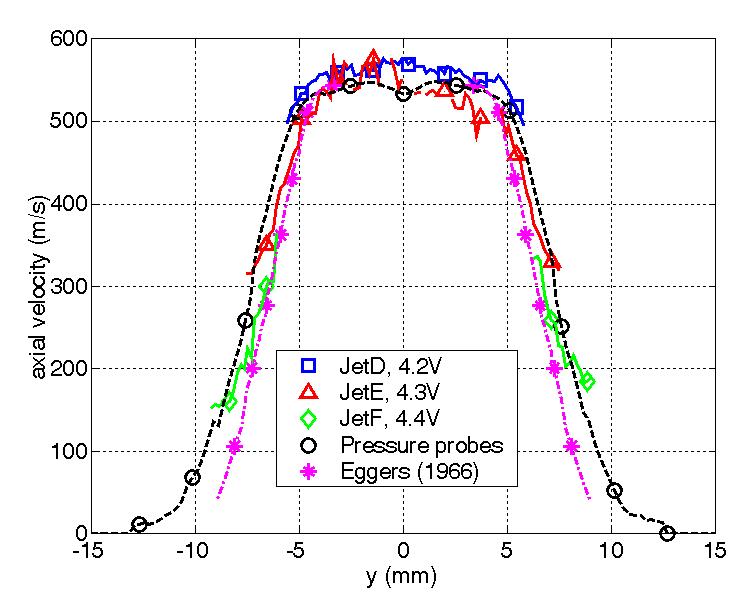

In addition to the two methods discussed above, velocity data was also available from

Eggers 1966 survey of a 1" diameter M=2.22 free jet. Comparing the three sets of data

as shown below, it can be seen that the agreement is only fair. While the Pitot

measurements may suffer from centerline offset O(0.1D(Pitot)), this is not enough to

explain the differences between the present Pitot data and that of Eggers. The main

reason for this is believed to be that the scaled boundary layer thickness in the 1967

survey was thicker than in the present experiment.

The FRS data acquired at three different laser setpoints show significantly different

velocity (40 m/s) in the shear layer in overlapping regions where two setpoints were

expected to produce data of similar quality. In the uncertainty analysis, several

sources of velocity uncertainty were established. The most significant source was

found to be laser drift (35 m/s), followed by velocity profile broadening due to

turbulence and thermal velocity (12 m/s), image overlap (11 m/s), shot noise

(10 m/s) and whitefield correction error (7 m/s). Note that these are rather

conservative estimates and that the maximum errors typically occur at different

parts of the acquired image. The size of these errors made it clear that in order

to achieve <10 m/s accuracy in velocity measurements, frequent recalibrations of the laser, or better still, monitoring

and adjusting the laser wavelength during the run would be needed along with

a model that can account for the scattered spectrum in a case with significant

seeding in the flow.

Future Work

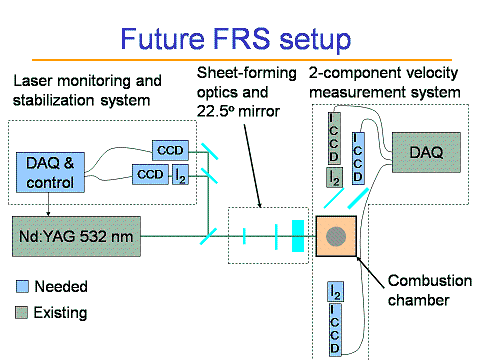

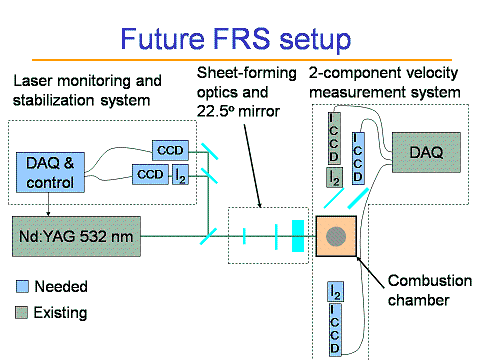

Currently (June 2008), Jignesh Sutariya is setting up a more advanced FRS experiment where

a feedback system will be used to correct the laser drift and two filtered ICCDs will be used

to determine two velocity components in the flowfield in a high-pressure combustion chamber.

Below are two diagrams of the planned setup.

Left: Schematic of 2D FRS setup showing the necessary components to measure two velocity components in the

chamber while maintaining constant laser wavelength.

Right: New high-pressure test chamber with improved 4-way

optical access.

Related publications

You may order the complete dissertation from LuLu as Order # 8513360. An abstract can be found here (pdf).

Links

Back to the UF research page

Older FRS page

Brief literature survey page

FRS page of the Applied Physics Group (Richard Miles, Princeton)

FRS page of Gasdynamics and Laser Diagnostics Research Laboratory (Gregory Elliott, UIUC) (very nice page!)