Air Emissions at a Wastewater Treatment Plant |

Although the primary concern of a wastewater treatment plant (WWTP) is to remove contaminants and inactivate pathogens in the wastewater to protect human and environmental health, there are also several air emissions that should be considered in the quest to protect human and environmental health. Air emissions from WWTP are a health concern for the plant operators and a nuisance concern for neighbors.

A plant operator at the University of Florida wastewater treatment plant.

Contaminants such as pathogens and volatile organic compounds can become airborne in the process of treating the water, especially at sites of gaseous releases or mechanical agitation, such as denitrification, aeration, or mechanical oxidation. Another common site of high airborne emissions can be at the exit of pipe transport.

A mechanical oxidation device, a common way for pathogens and VOCs to become airborne.

Confined spaces are especially important for WWTP employees because they receive minimal ventilation, allow emissions to accumulate in these places at unusually high concentrations. A confined space can be any number of places at a WWTP, from sewer lines to tanks, such as that shown in the picture below.

Large tanks such as this at the UF WWTP have poor ventilation and are especially susceptible to high concentrations of airborne emissions and require special consideration if maintenance is required.

Upon entrance to a confined space, OSHA requires operators to wear gas badges, as shown in the following graphic, to continuously monitor exposure levels.

Photo from Sentry Safety Supply, sentrysafetysupply.com

Some of the main include nuisance odororous compounds (hydrogen sulfide, mercaptans, and ammonia), volatile organic compounds (such as hydrocarbons), and bioaerosols.

Hydrogen sulfide is formed during the anaerobic reduction of sulfur by sulfate reducing bacteria. Sulfur is available in WWTP as either organic sulfur from feces or inorganic sulfur from the sulfate ion, which is prevalent in nearly all water. Hydrogen sulfide causes an offensive rotten egg smell which can be detected at very low concentrations. It also can be toxic and even fatal at higher concentrations, although more common symptoms include dizziness, headaches, and nausea. The emissions can also corrode pipes, causing expensive maintenance fixes.

Hydrogen sulfide pipe corrosion, courtesy of New Mexico Tech Water and Infrastructure Data System http://octane.nmt.edu/WaterQuality/corrosion/H2S.htm

Hydrogen sulfide emissions for nuisance concerns are not nationally regulated, but some states and cities have their own requirements, often depending on the proximity of the plant to people to prevent nuisance odors. Examples of these standards can range from 10-100 ppb due to the low detection threshold of the compound. To protect the health of WWTP operators, OSHA requires that operators not be exposed to more than 50 ppm for over a ten minute period. These high levels are frequently only reached during entrance into a confined space. Gas meters must be worn during such work to provide a warning, and co-workers are required to stand by during the entire maintenance period. Although hydrogen sulfide's strong odor is a good indicator, exposure to a high concentration for a short period can destroy a sense of smell, which might lead to a false sense of security. Hydrogen sulfide is often controlled using scrubbers, biofilters, or upstream chemical addition. Its formation can be prevented by minimizing anaerobic conditions.

Other odorous compounds include mercaptans and ammonia. Mercaptans are the organic equivalent of hydrogen sulfide, producing odors ranging from skunk-like to decayed cabbage.

Volatile organic compounds (VOCs) are often categorized as Hazardous Air Pollutants (HAPs). They are formed by the volatilization of organic compounds in the treatment process. Industrial processes are often the source of these organic compounds present in wastewater. VOCs are associated with health effects, and also cause safety problems due to common characteristics such as flammability. Emissions of VOCs are regulated by the Hazardous Air Pollutant component of the Clean Air Act Amendments of 1990. Releases must be reported to the Toxic Release Inventory, which is accesible to the public. For safety and insurance purposes, the concentration frequently cannot exceed 25% of the Lower Explosive Limit for that compound. VOC control options include biofiltration, incineration, and carbon adsorption.

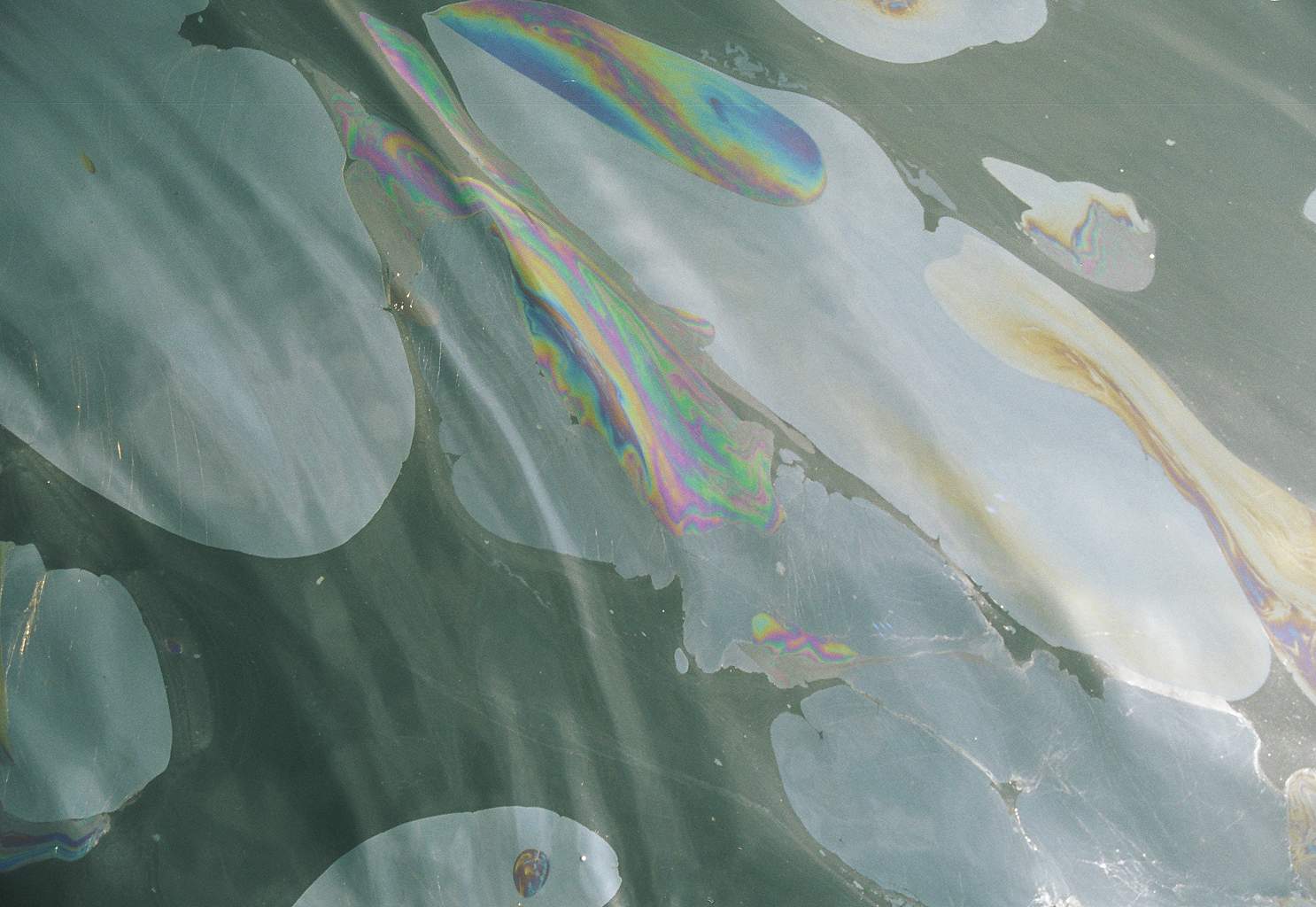

Oil slick on water, photo courtesy of UCSB Geology Department http://www.geol.ucsb.edu/faculty/valentine/Hydrocarbon%20Weathering.htm

Bioaerosols are defined as any airborne particle that is organic in origin. At a WWTP, the main concern is to prevent the release of pathogenic microorganisms, which are inherent to the WWTP process. Types of pathogenic microorganisms can include cryptosporidium, giardia, or Legionella. Pathogenic bioaerosols are especially a concern for WWTP that receive discharges from hospitals, where patients are being treated for several different diseases and infections. Inhalation or ingestion of a certain amount of these (known as the Minimum Infectious Dose) can lead to significant illnesses. It is mostly a concern for operators. Although most regulations focus on required removal from the water, all plants should use best management practices to minimize airborne exposure and subsequent health effects. These can include frequent hand washing, showering and changing clothes before leaving work, bandanging any open wounds, and wearing respirators.

Schematic of a viral pathogen, courtesy of the University of California Museum of Paleontology http://www.ucmp.berkeley.edu/alllife/virus.html

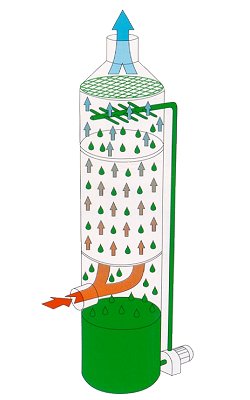

A control device was designed for hydrogen sulfide control from a hypothetical wastewater treatment plant. The hypothetical plant was designed combining waste stream data from a plant in Orlando, FL, and the current University of Florida operating conditions and location. A scrubber was chosen to help control the odors.

Typical wet scrubber, schematic courtesy of Forbes Plastic Tanks and Environmental Technologieshttp://www.forbesgroup.co.uk/product.php/78/33/

The following detail the design of the wet scrubber.

| Summary of Operating and Design Parameters | ||||||

| G | 27.86 | kg/min | mass gas flow rate | |||

| L design | 43.23 | kg/min | design liquid mass flow rate | |||

| y 1 | 0.00005 | inlet waste stream concentration | ||||

| y 2 | 0.000001 | outlet waste stream concentration | ||||

| x 2 | 0.00 | inlet liquid concentration | ||||

| x 1 | 0.0000196 | outlet liquid concentration | ||||

| h | 98.00% | required removal efficiency | ||||

| diameter | 1.117 | m | tower diameter | |||

| Z T | 5.495 | m | Tower height | |||

| D P tot | 6.308 | in H 2 O | Total pressure drop | |||

| Cost Summary for Entire System (two towers) | ||||

| Total Installed Cost | $122,792.13 | capital investment | ||

| Total Operating Costs | $13,122.27 | annual | ||

| Media Replacement Costs | $2,134.13 | once every 4-5 years | ||

This project was brough to you by: