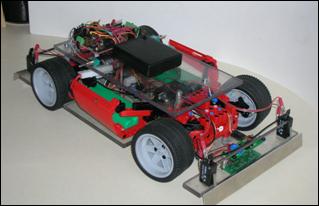

Ferrarobot

Kyle L. Carithers

Intelligent

Machines Design Lab

Spring

2006

Mechanical

devices

The typical setup used in constructing most robots in

this class includes two wheels with a motor attached to each, “TJ”

style, or differential drive. The

two wheels both power and steer.

The robot turns by applying a greater voltage to one motor or the

other. This system does have some

drawbacks.

The main drawback to this system is that two motors

will supply at least slightly different power. A robot in this setup will experience

difficulty driving straight. In most

cases, the robot will have to use a third roller or swivel wheel. The size of the robot is limited in this

setup because of the torque required to overcome the friction involved.

For Ferrarobot, I chose to build the robot to

simulate car-like driving. This

involves rack and pinion steering and rear wheel drive powered by a single

motor. The benefit of this setup is

that the robot should have little problem traveling straight. There is a single motor that applies an

even amount of torque to each wheel.

A larger robot can be constructed that does not require a high friction

third wheel. The rear wheels can

focus on driving while the front wheels can focus on steering.

One of the major disadvantages of this system is

that steering becomes much more complicated. The front steering wheels now have to

rotate together. The complicated

mechanical aspect of this type of steering is a major reason for why I chose to

incorporate Lego products into my design.

Another disadvantage is that with this setup, the robot has a turning

radius. In the two wheel setup, if

the robot must go to a specific object forward and to the left, the robot can

stop, turn towards the point, and then move in a generally straight

direction. In the front wheel drive

setup, it must go forward and left at the same time. Programming the robot becomes more difficult

as it must account for this turning radius.

Steering

Column

I built the rack and pinion steering system from

Lego pieces in such a way that it could be bolted directly to the polycarbonate

platform eliminating the need for any type of connecting piece. A Lego shaft connects the servo to the

pinion gear. The pinion gear meshes with the rack gear. When the servo rotates, the pinion

rotates and the rotation is converted into translation of the rack. The rack is

connected to each wheel hub by a rod. Each hub is mounted by a ball and socket

joint and rotates with translation of the rack.

Pinion Gear

Rack Gear

Differential Gear

Differential Gear

Using a single motor has clear benefits. In most cases though, using one motor

requires using a single, connected axle.

A problem arises when wheels must rotate at different speeds, which

would occur any time the robot is turning.

A single axle of course does not allow for wheels at each end to rotate

at different speeds. If a turn is

attempted, then slip must occur, meaning a tire would slide against the road or

other surface. When dealing with

larger robots or vehicles, more weight and friction is involved. This makes slipping harder because it

requires a greater force and makes turning much more difficult because turning

in this case requires slipping in the rear wheels.

To allow each wheel to rotate at a different spend,

avoid slipping, and improving the ease of turning a differential is used. The differential applies an equal amount

of torque to each wheel but allows for the wheels to rotate at different

speeds. The best way to explain how

this is done is by showing the system under various conditions.

In this picture, from Wikipedia,

both wheels would be turning.

Assuming that a motor applies torque to the blue gear and that the red

and yellow gears rotate at the same velocity, the green gear would apply an

equal torque to both the red and yellow gears. This could occur when the robot is

traveling either forwards or backwards.

In this picture, from Wikipedia,

both wheels would be turning.

Assuming that a motor applies torque to the blue gear and that the red

and yellow gears rotate at the same velocity, the green gear would apply an

equal torque to both the red and yellow gears. This could occur when the robot is

traveling either forwards or backwards.

In this picture, also from

Wikipedia, the wheel attached to the yellow gear would be turning. Assuming that a motor applies torque to the

blue gear and that the red and yellow gears rotate at the same velocity, the

green gear would apply an equal torque to both the red and yellow gears. This could occur when the robot is

turning, although there would likely be some rotation of the red gear.

In this picture, also from

Wikipedia, the wheel attached to the yellow gear would be turning. Assuming that a motor applies torque to the

blue gear and that the red and yellow gears rotate at the same velocity, the

green gear would apply an equal torque to both the red and yellow gears. This could occur when the robot is

turning, although there would likely be some rotation of the red gear.